Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

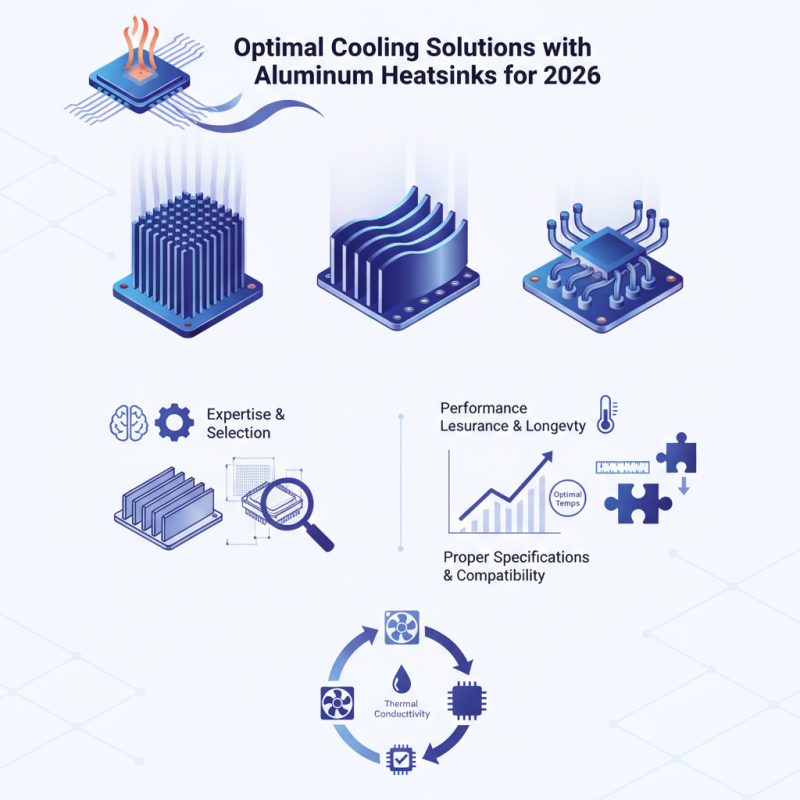

In the ever-evolving world of electronics, effective cooling solutions are paramount. Aluminum heatsinks have emerged as a reliable option in this space. Industry expert Dr. Emily Chen once stated, “Efficient thermal management is crucial for device performance.” This highlights the significance of selecting the best aluminum heatsinks available.

Aluminum heatsinks offer excellent thermal conductivity, allowing devices to maintain optimal operating temperatures. They come in various shapes and sizes, tailored to meet specific requirements. However, not all aluminum heatsinks deliver the same performance. Some designs are outdated and less effective. This can make choosing the right heatsink a daunting task.

A well-designed aluminum heatsink can significantly enhance performance and longevity. Yet, many users overlook the importance of determining the proper specifications. A mismatch in dimensions or material can lead to inefficient cooling. This is an area where careful consideration and expertise play a vital role in achieving desired outcomes.

Aluminum heatsinks play a vital role in cooling electronic devices. They effectively dissipate heat generated by components like CPUs and GPUs. With their lightweight design, aluminum heatsinks are commonly chosen for a variety of applications. They come in many shapes and sizes, tailored for specific needs. The fin design can vary, affecting heat dissipation efficiency.

These heatsinks need to be properly integrated into systems. Poor contact between the heatsink and the component can lead to inadequate cooling. Thermal paste is often used to improve this connection, yet it must be applied correctly. Over-application can create air bubbles, while under-application might not provide enough coverage. This delicate balance requires careful consideration.

In some cases, the choice of heatsink can be a challenge. Factors such as size, weight, and thermal performance must all be weighed. A heatsink that is too large might not fit in compact designs. Conversely, a small heatsink might not provide sufficient cooling. This trial-and-error approach can be frustrating but is often necessary to achieve optimal performance. Understanding these nuances is essential for engineers and hobbyists alike.

| Heatsink Type | Dimensions (mm) | Weight (g) | Thermal Resistance (°C/W) | Application |

|---|---|---|---|---|

| Extruded | 100 x 50 x 20 | 150 | 5.0 | LED Lighting |

| Pinned | 80 x 80 x 25 | 100 | 3.5 | CPU Cooling |

| Finned | 120 x 60 x 30 | 180 | 4.5 | Graphics Cards |

| Natural Convection | 90 x 45 x 40 | 120 | 6.0 | Power Electronics |

| Active Cooling | 110 x 50 x 50 | 200 | 2.0 | High-Performance CPUs |

When choosing aluminum heatsinks, it’s vital to consider key features that impact cooling performance. The material thickness influences heat dissipation. Thicker heatsinks usually provide better thermal conductivity, but they may increase weight. Weight matters in design; ensure it suits your application.

Another crucial aspect is the surface area. A larger surface area allows for more heat exchange. Fins and additional structures can enhance this feature. However, some designs might complicate assembly, which is a factor to weigh.

Lastly, consider the airflow around the heatsink. Active cooling methods can complement passive designs. Fans can boost airflow, but they introduce noise. Balancing performance and comfort may require some testing. Choosing the right heatsink is not just about specifications; it's about real-world application and efficiency.

When selecting aluminum heatsinks for optimal cooling solutions in 2026, it's essential to explore various models. Key factors include size, performance, and compatibility with your devices. Some heatsinks excel in compact spaces, while others cater to larger systems. The right choice depends on your specific application.

**Tips:** Consider the thermal conductivity of the aluminum. Higher conductivity often leads to better heat dissipation. Additionally, check for surface treatments that enhance performance.

Another vital aspect is airflow. A well-designed heatsink works with existing airflow. However, not all designs consider this. Some may obstruct airflow, leading to inefficiency. Assess how the heatsink aligns with fans and ventilation before making a choice.

**Tips:** Always review user feedback. Real-world experiences provide insights that specs can overlook. Look for models that strike a balance between size and cooling capacity for your needs.

When it comes to thermal management, aluminum heatsinks stand out for their efficiency. This metal is lightweight and has excellent thermal conductivity. The cost-effectiveness of aluminum makes it popular in various applications. However, it may not be the best choice for every scenario. In some cases, copper heatsinks have superior thermal performance. They can absorb and dissipate heat more efficiently. Yet, copper is heavier and comes with a higher price tag.

Comparatively, plastics and ceramics have emerged in niche markets. They are often lighter and cheaper, benefiting unique designs. However, their thermal properties generally lag behind metals. For high-performance applications, the gap in efficiency can become significant. Some users may find that a hybrid approach works best. Combining materials could lead to ideal cooling solutions. Despite advancements, finding the perfect heatsink remains a challenge. Users often need to balance cost, weight, and thermal performance. It's a process of trial and error. Each project can yield different results.

When it comes to aluminum heatsinks, installation plays a vital role in maximizing cooling efficiency. A proper mounting technique ensures optimal heat transfer between the heatsink and the component it cools. Using thermal paste improves conductivity. Apply it evenly. Be cautious; too much can create a barrier rather than enhance performance.

Consider the airflow around the heatsink. Position it where air circulates freely. Fans should direct cool air towards the heatsink. This can significantly reduce temperatures. Blocking airflow with cables or other components is common but detrimental. Take time to organize cables for better airflow.

Check for compatibility. Not all heatsinks fit every application. Measure the space available. Some designs may require more room for optimal function. It's essential to avoid forcing a heatsink into an incompatible space. This can lead to inefficiencies and potential damage. Regularly revisiting the setup can help identify areas for improvement. Each installation can teach us something new.