Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving field of temperature control sensors, industry experts highlight the importance of precision and reliability. David Thompson, a recognized expert in thermal management, once noted, "Accurate temperature control is vital for innovation in various sectors." As we look ahead to 2026, the technological advancements in temperature control sensors will become even more critical.

The landscape of temperature control sensors is changing. Businesses are constantly seeking sensors that not only deliver accuracy but also integrate seamlessly with smart technology. This shift is crucial for industries like healthcare, where temperature management can affect patient safety. The challenge lies in balancing innovation with practicality.

Amid these advancements, some sensors still struggle with calibration and durability. This inconsistency can lead to performance issues. Companies must evaluate their options carefully. Future temperature control sensors should prioritize user-friendly designs and robust functionality. As we strive for the best, the journey remains a work in progress.

Temperature control sensors are vital in various industries in 2026. They measure and regulate heat effectively. Different types of sensors are available, including thermocouples and thermistors. Each type has unique features and applications.

One significant trend is the integration of smart technology. Many sensors can now communicate with smartphones and other devices. This feature allows for real-time monitoring from anywhere. Users can receive alerts if temperatures deviate from set levels. It adds convenience but can lead to over-reliance on technology. Sometimes, manual checks are still necessary.

Tips: Always calibrate your sensor regularly. Accurate readings are crucial for optimal performance. Consider the environment where the sensor will be used. Certain sensors perform better in specific conditions. Assessing your needs will lead to better choices. Remember, the best sensor is not always the most advanced one. Sometimes, simplicity is key!

When selecting a temperature control sensor, precision is vital. Look for sensors that can detect minute temperature changes. This feature ensures that processes maintain optimal conditions. A high level of accuracy can prevent costly mistakes in various applications. For instance, in manufacturing, a slight temperature fluctuation may lead to defective products.

Another important aspect to consider is the response time. Some sensors react swiftly, while others may lag. Fast response times are crucial in dynamic environments. Delays can compromise safety or efficiency. Additionally, durability matters. A sensor must withstand harsh conditions, such as extreme temperatures or humidity.

Lastly, consider the ease of integration with existing systems. Some sensors can be cumbersome to install. This can lead to installation delays. A simple setup process is often overlooked yet essential. Reflecting on these features allows for a better choice. Always weigh the pros and cons of each option carefully.

Temperature control sensors have significantly evolved in 2026. They are now more accurate, reliable, and efficient. These sensors play a crucial role in various industries, including healthcare and manufacturing. A key technology gaining traction is fiber optic sensors. They offer high sensitivity and the ability to monitor temperature changes over long distances. However, they can be expensive and complex to install.

Wireless temperature sensors have emerged as another game changer. With advancements in battery life, these devices allow for real-time monitoring. They can be placed in locations that are hard to reach. Yet, signal interference may sometimes affect their performance. This is an area that needs improvement.

One promising development is the integration of artificial intelligence. AI can analyze temperature data patterns, predicting fluctuations before they occur. This enhances preventive measures. Still, the reliance on technology raises concerns about cybersecurity risks. Manufacturers must focus on securing these devices against potential breaches. Balancing innovation and safety is essential for future growth.

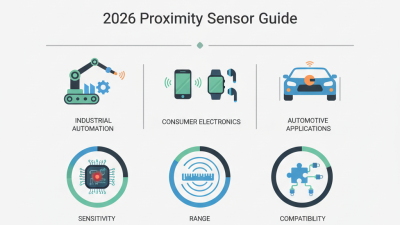

In 2026, the race for the best temperature control sensor has intensified. Various technologies have emerged. Each sensor type offers unique advantages, but also challenges. For instance, infrared sensors are fast and non-contact, yet they sometimes struggle with accuracy. Users report inconsistent readings due to environmental interference.

Thermocouples are widely used due to their reliability. They excel in extreme temperatures but can be expensive. Calibration is crucial, as improper setup leads to errors. Some find them difficult to integrate with automated systems.

On the other hand, resistance temperature detectors (RTDs) provide excellent precision. However, their response time can be slow. They often require complex circuitry, which might not suit all applications.

Overall, the decision-making process remains complex. Feedback from users highlights the importance of understanding specific needs. Performance, cost, and integration play significant roles. Each sensor has its merits and flaws. The ideal choice varies depending on individual requirements and use cases.

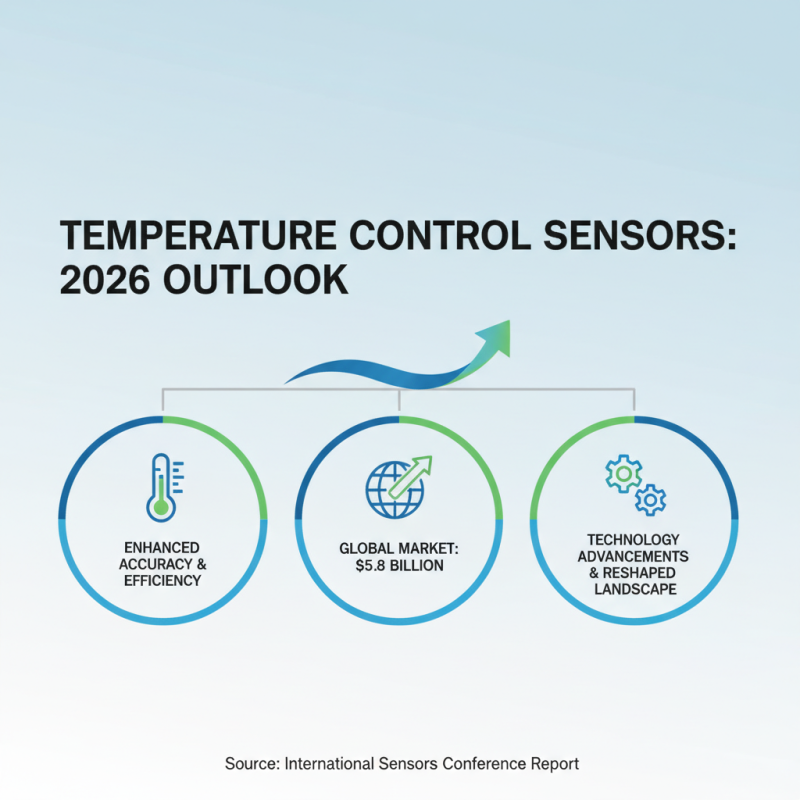

In 2026, temperature control sensors are set to undergo significant advancements. Emerging technologies point to enhanced accuracy and efficiency. According to a recent report by the International Sensors Conference, the global temperature sensor market is expected to reach $5.8 billion by 2026. This growth will likely reshape the landscape.

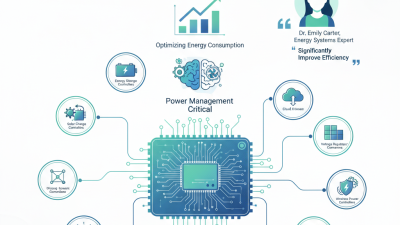

Innovations in microelectromechanical systems (MEMS) are driving this change. MEMS sensors offer miniaturization and high sensitivity. They provide real-time data with minimal power consumption. However, the integration of these sensors into existing systems presents challenges. Companies may struggle to implement new sensors without overhauling infrastructure.

Furthermore, there is a pressing need for improved calibration methods. A study from the Advanced Measurement Institute highlighted that around 20% of current sensors show noticeable drift over time. Addressing these issues can enhance reliability. The future requires a balance between innovation and practicality. Many organizations will have to rethink their strategies as new solutions become available.