Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right Digital Temperature Controller can be a daunting task. With so many options available, it's easy to feel overwhelmed. These controllers play a crucial role in various applications, from home brewing to industrial processes. Pinpointing your specific needs is essential.

Consider the features you require. Some controllers offer basic functions, while others provide advanced customization. Think about the temperature range you need and how precise you want the control to be. Personal preferences matter too. Do you prefer ease of use or advanced settings?

Reflect on your previous experiences with temperature control. What worked well? What didn’t? Each decision impacts performance and efficiency. Making the right choice can enhance your setup. On the contrary, the wrong controller may lead to frustration. Therefore, understanding your requirements is indispensable. This journey to select the perfect Digital Temperature Controller can lead to valuable insights and new perspectives.

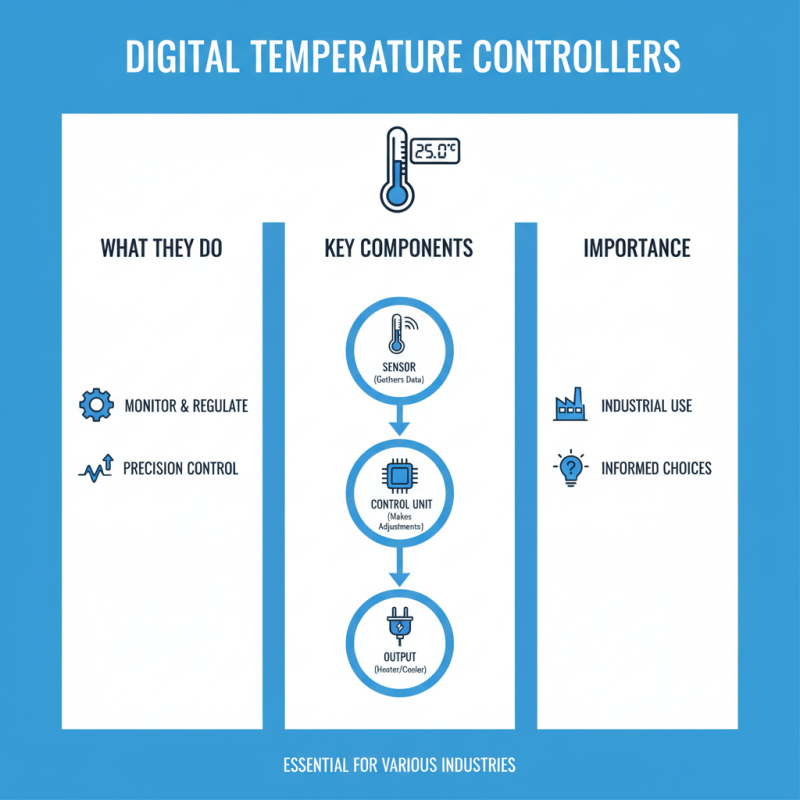

Digital temperature controllers are essential in various industries. Understanding their basics is crucial for making an informed choice. These devices monitor and regulate temperature with precision. They typically include a sensor, a control unit, and an output component. Sensors gather real-time data, while the control unit makes adjustments to achieve the desired temperature.

Tips: Consider the sensor type that suits your application best. Thermocouples are common, but RTDs offer higher accuracy. Check for compatibility with your existing systems to avoid integration issues.

Many reports highlight the growing demand for digital temperature controllers. A recent industry study projects the market growth rate at 6.5% annually. This surge indicates their importance across sectors such as food processing, pharmaceuticals, and HVAC systems. Installation can be complex. Ensure proper calibration and programming to avoid inaccuracies.

Tips: Choose a controller with user-friendly software. It should allow easy adjustments and monitoring. Review user experiences to identify potential frustrations. Sometimes, even minor adjustments can make a significant impact on efficiency. Remember, not all controllers are created equal. An ill-fitting choice can lead to failures in maintaining the right environment.

When choosing a digital temperature controller, understanding your specific temperature control requirements is crucial. Identify the range of temperatures you need for your application. Reports indicate that industries like food and beverage often require precise control within 1°C. Meanwhile, scientific labs may need even tighter tolerances.

Next, consider the environment where the controller will operate. Industrial settings may expose devices to dust or moisture, potentially impacting functionality. According to a study by the International Society for Automation, 30% of temperature control failures result from environmental factors. Therefore, selecting a controller with adequate protection ratings is vital.

Furthermore, evaluate the features you may need. Some controllers offer remote monitoring, while others provide data logging options. An overwhelming 65% of users report that logging data has improved their processes. However, additional features can complicate usage. A simple interface might be more beneficial than a multitude of options. Balancing ease of use with advanced features can be tricky. Reflecting on these details can lead to a more informed choice.

When selecting a digital temperature controller, assessing their features is crucial. Controllers come in various types, each with specific functionalities that cater to different needs. Look for a controller with a clear display. A user-friendly interface makes monitoring easy. Adjustable set points allow for flexibility in temperature control based on your unique requirements.

Consider the accuracy and response time of the controller. Some models may advertise great precision but fail in real-world applications. You want a device that reacts quickly to temperature changes. Many users overlook this detail, leading to potential issues. Additional features like alarms and data logging can provide valuable insights.

Another aspect to consider is connectivity. Some controllers offer Wi-Fi or Bluetooth options. This connectivity facilitates remote monitoring and control. While convenient, it can also introduce complexity. A well-connected device may have a steeper learning curve. Reflect on what suits your comfort level. Not every feature may be necessary. Choosing wisely means understanding what you truly need.

| Feature | Description | Importance |

|---|---|---|

| Temperature Range | The range of temperatures that the controller can measure and regulate. | Essential to ensure it meets the operational needs. |

| Accuracy | The precision of the temperature readings provided by the controller. | High accuracy is crucial for consistent results. |

| Display Type | The kind of display used (digital, analog, touchscreen, etc.). | Affects ease of use and visibility of readings. |

| Control Type | The method of control used (on/off, PID, etc.). | Determines responsiveness and stability in temperature control. |

| Additional Features | Other functionalities, such as alarms, logging, and remote access. | Enhances user experience and control capabilities. |

| Power Supply | The required power specifications and options (AC, DC, battery). | Important for compatibility with existing systems. |

| Size and Mounting Options | Dimensions and installation options (panel mount, DIN rail, etc.). | Affects installation space and convenience. |

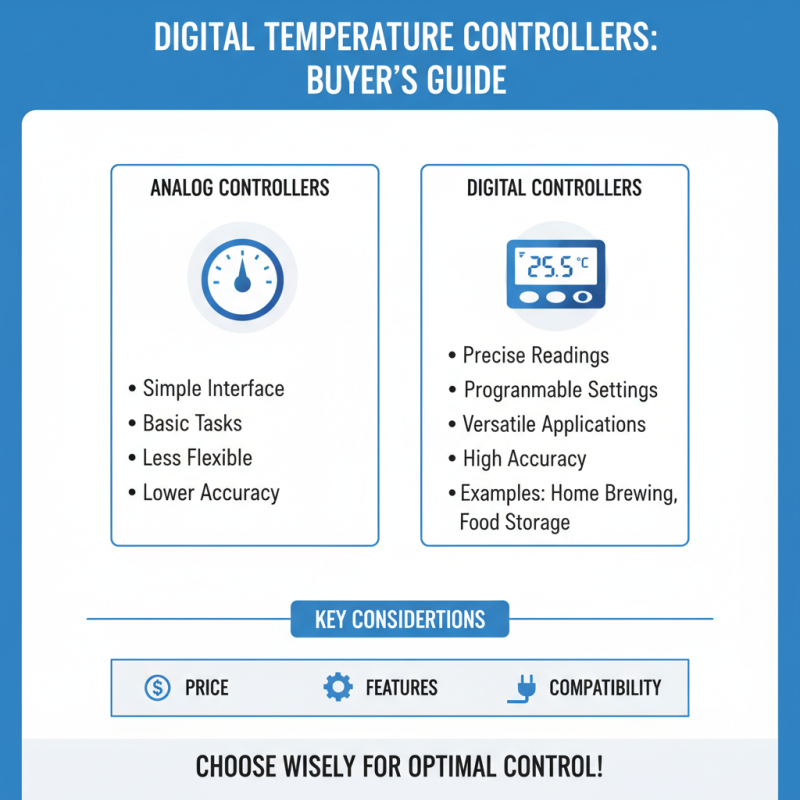

When considering a digital temperature controller, you will find various types and models available in the market. Price, features, and compatibility are key factors to think about. Analog controllers provide simple interfaces for basic tasks. However, they may lack flexibility and accuracy for detailed operations. In contrast, digital controllers offer precise readings and programmable settings, which cater to various applications like home brewing and food storage.

Each model has distinct advantages and disadvantages. For instance, some advanced controllers come with Wi-Fi capability. This allows remote monitoring, but it can be complicated for novice users. Many users report issues with initial setup and integration into existing systems. Similarly, temperature range is critical; some models cannot handle extreme temperatures. Therefore, evaluating specific requirements is vital.

Lastly, consider user reviews when selecting a model. Often, feedback highlights common pitfalls that can be avoided. Additionally, don't rush your decision. Spend time understanding the features of each product. This process can help avert future frustrations.

When choosing a digital temperature controller, evaluating budget and long-term maintenance costs is essential. Prices can vary widely based on features and accuracy. According to industry reports, investing in a higher-end model can reduce energy costs by up to 25% over time. This not only helps in immediate savings but also improves efficiency and reliability.

Tip: Start by assessing your specific needs. Consider how much control you require. For less demanding applications, a simpler model may suffice. However, complex systems might need advanced features that come with a higher initial price tag.

Long-term maintenance should not be overlooked. Some controllers may require regular calibration or replacement parts. This can impact your overall budget significantly. Reports suggest that neglected maintenance can lead to failure rates increasing by over 30%. This might incur additional repair expenditures or downtime.

Tip: Always factor in potential maintenance costs when making a decision. A lower upfront cost doesn’t always translate to value in the long run. Instead, focus on the cost-effectiveness of the controller according to your operation’s demands.