Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

When selecting a Temperature Control Sensor, understanding your specific needs is vital. According to industry reports, nearly 30% of consumers struggle with sensor accuracy. This can lead to inefficiencies and increased operational costs. In sectors like HVAC and food processing, precision in temperature control isn’t just a luxury—it’s critical. A minor error can spoil goods or compromise safety.

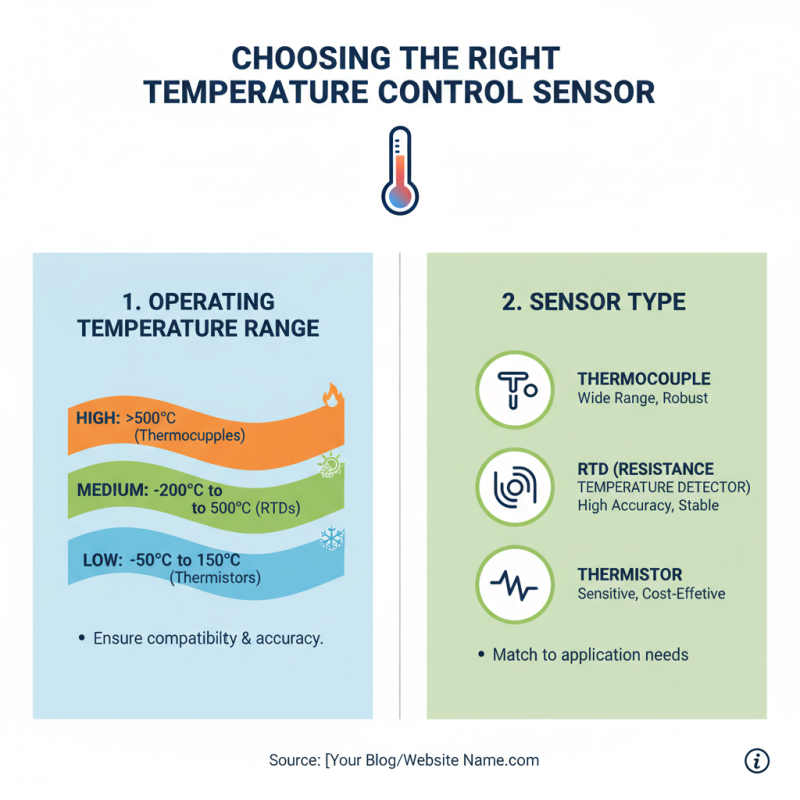

Temperature Control Sensors come in various types, including thermocouples and RTDs. Each sensor type has unique characteristics. Choosing the wrong sensor type can lead to significant measurement inaccuracies. The right choice depends on the application environment, required accuracy, and response time. A mismatch here creates issues that could have been easily avoided.

Moreover, market data indicates that over 40% of facilities report high maintenance costs linked to poor sensor performance. This suggests a pressing need for better decision-making when it comes to sensor selection. It’s essential to evaluate options thoroughly. Inadequate research may result in long-term setbacks that are hard to overcome.

When it comes to temperature control sensors, understanding the various types available is crucial. Common types include thermocouples, thermistors, and infrared sensors. Thermocouples are widely used in industrial settings due to their durability and wide temperature range. According to a recent industry report, they account for approximately 45% of the market demand for temperature sensors. Their ability to withstand harsh environments makes them a favored choice.

Thermistors, on the other hand, are often used in medical and HVAC applications. They provide high sensitivity and accuracy within a limited temperature range. Data indicates that thermistors make up about 20% of temperature sensors used today. However, their performance dramatically varies in extreme temperatures. It's essential to assess the application requirements carefully.

Infrared sensors are non-contact devices used in various settings, from manufacturing to food safety. These sensors can quickly measure surface temperatures without touching the object. While they offer flexibility, they may not measure internal temperatures accurately. Although infrared sensors are growing in popularity, they account for only 15% of the market. Users must be aware of these nuances when choosing the right sensor for their needs.

Choosing the right temperature control sensor requires careful consideration of several factors. One key factor is the operating temperature range. Different sensors are designed for specific ranges. Knowing your range ensures compatibility and accuracy. Another factor is the sensor type. Thermocouples, RTDs, and thermistors each have unique characteristics. Depending on your application, one may be more suitable than the others.

Accuracy is crucial. Some sensors provide greater precision than others. This difference can impact critical applications, like medical devices or food processing. Response time is also important. Some sensors react quickly to temperature changes, while others may lag. In dynamic environments, quick response is essential.

Installation challenges should not be overlooked. Ensure that the sensor can be easily integrated into your system. Consider environmental factors as well, such as humidity or potential interference. Reflect on your specific needs carefully. A sensor may seem perfect but could fall short in real-world conditions.

When choosing a temperature control sensor, accuracy and precision are paramount. Both terms may seem similar, but they refer to different aspects of measurement. Accuracy means how close the measurement is to the true value. Precision refers to the consistency of repeated measurements. Understanding these differences helps in selecting the right sensor.

In applications like food safety, even a small deviation can lead to significant issues. Sensors that are accurate within 1°C may suffice in casual settings. However, for research applications, a deviation of 0.1°C may not be acceptable.

Tip: Always define your requirements before purchasing. Determine the acceptable limits for accuracy and precision based on your specific application.

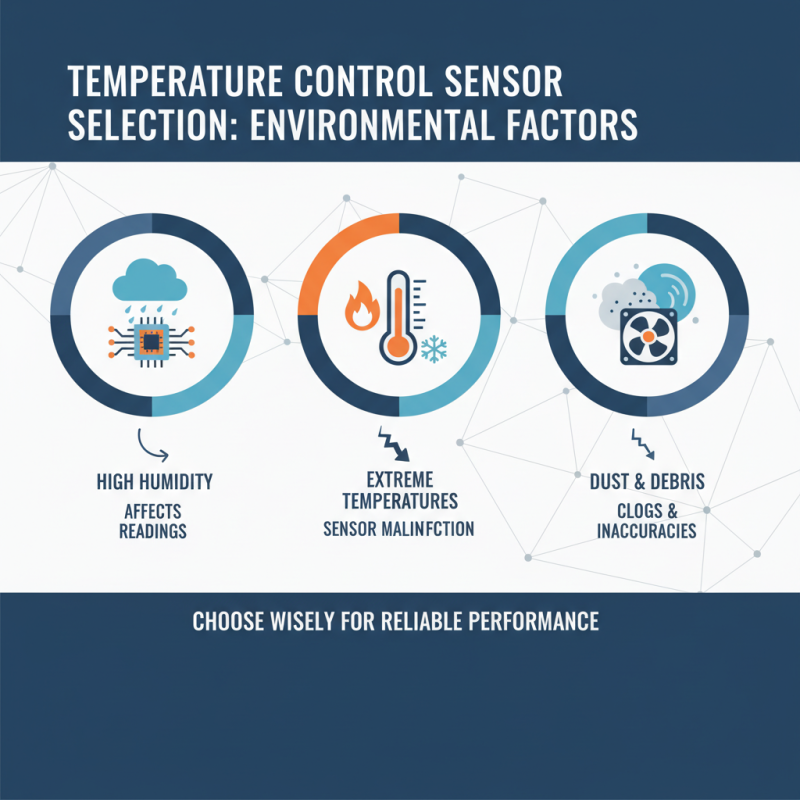

Another factor is environmental conditions. Some sensors perform well in controlled environments but fail in extreme temperatures or humidity. Check the specifications for your sensor to ensure it can handle the conditions you'll encounter.

Tip: Consider how often you will take measurements. If you need regular monitoring, a more precise sensor will pay off in the long run.

Balancing accuracy, precision, and environmental resilience can be challenging. It's crucial to reflect on how these factors align with your particular needs. Don't overlook the potential trade-offs.

Choosing the right temperature control sensor involves more than just specifications. It requires careful consideration of environmental conditions. Different environments can significantly impact sensor performance. For instance, high humidity can affect readings. On the other hand, extreme temperatures might lead to sensor malfunction.

Understanding your surroundings is crucial. Sensors located in industrial settings face vibrations and dust. These conditions can hinder accurate readings. In contrast, sensors in clean, controlled environments experience fewer interferences. It’s essential to assess these factors early on, as they directly influence sensor accuracy and longevity.

The placement of sensors also matters. A poorly placed sensor may not capture true environmental conditions. For example, a sensor next to heat-generating equipment will yield inaccurate data. Evaluate the environment before installation. Consider adjusting sensor locations if needed. These decisions can be the difference between success and failure in temperature control.

When selecting a temperature sensor, cost and lifespan are crucial factors. According to industry data, thermocouples are often the most affordable option. They typically range from $10 to $500, depending on accuracy and application. While they offer a short lifespan, averaging around 2 to 5 years, their low initial cost makes them attractive for some projects.

In contrast, resistance temperature detectors (RTDs) tend to have a higher upfront cost. Prices can start at $50 and go up to $1,000. However, RTDs can last up to 10 years or more if maintained properly. This longevity can offset their initial expense, making them a wise investment in the long run. They are preferred in industries where precision is key.

Infrared sensors, on the other hand, are frequently used for non-contact temperature measurements. Their costs range significantly, from $100 to over $2,000. Despite their higher price, they provide instant readings and can be beneficial in hazardous environments. Yet, the need for calibration and potential drift raise concerns about reliability over time. These factors necessitate careful consideration before choosing the most suitable temperature control sensor for your needs.

| Sensor Type | Cost (USD) | Typical Lifespan (Years) | Accuracy (%) | Response Time (Seconds) |

|---|---|---|---|---|

| Thermocouple | 10 - 100 | 10 - 15 | ±1.5 | 0.5 |

| RTD | 50 - 200 | 20 - 25 | ±0.1 | 1 |

| Thermistor | 5 - 50 | 5 - 10 | ±0.5 | 2 |

| Infrared Sensor | 20 - 300 | 10 - 15 | ±2 | 0.1 |

| Bimetallic Sensor | 30 - 150 | 15 - 20 | ±2 | 3 |