Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

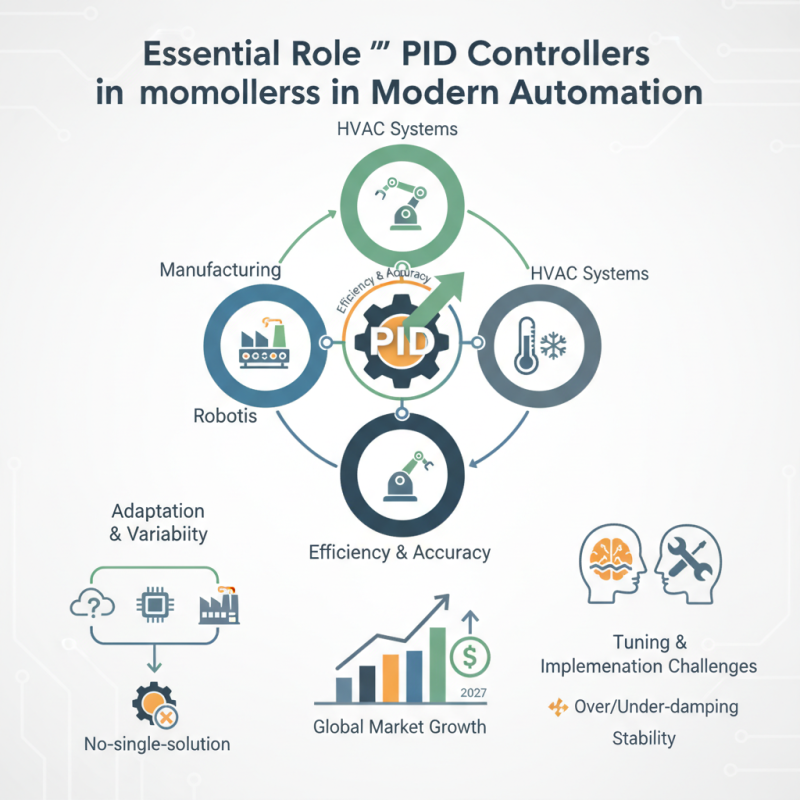

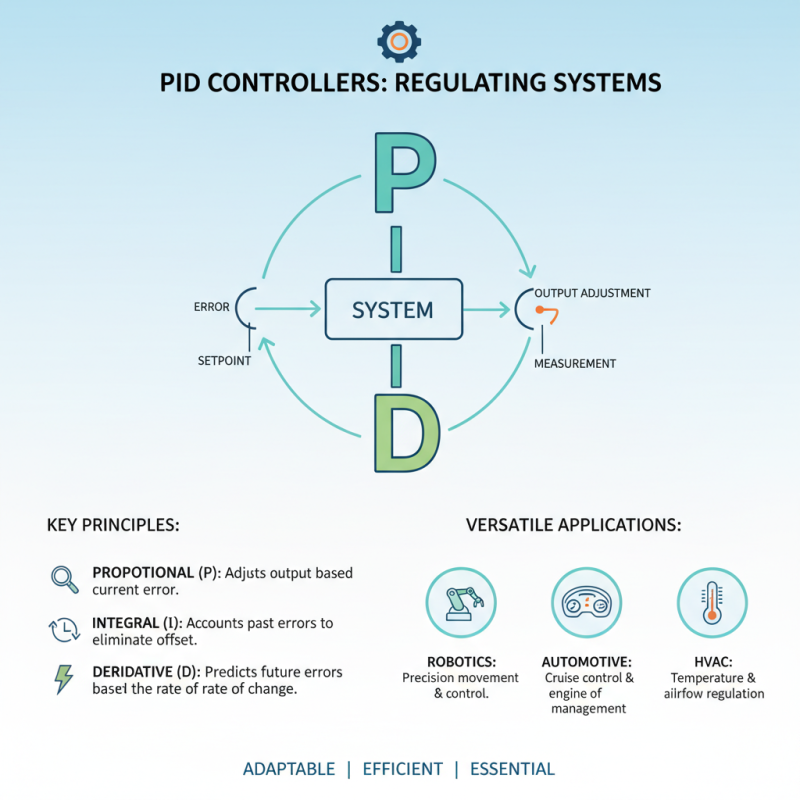

In modern automation, the Pid Controller plays a crucial role in enhancing system efficiency and accuracy. According to a report by MarketsandMarkets, the global PID controller market is projected to reach $5.5 billion by 2027, illustrating its growing importance across industries. It serves as the backbone for applications in manufacturing, robotics, and HVAC systems.

Dr. Emily Thompson, an expert in control systems, emphasizes the importance of Pid Controllers: "A well-tuned PID Controller can make or break system performance." This highlights the need for precision in tuning and implementation. Despite their widespread use, achieving the right parameters often proves challenging. Many engineers struggle with over- or under-damping issues, which can lead to instability in control processes.

Moreover, as industries evolve, so do the complexities of systems requiring continuous monitoring. There is a constant need to reflect on how Pid Controllers can adapt. Their effectiveness varies based on the specific application and environmental conditions. This variability serves as a reminder that no single solution fits all scenarios.

PID controllers play a vital role in modern control systems. These controllers help maintain desired outputs in various applications. Whether in industrial automation or temperature regulation, their importance cannot be overlooked. They adjust processes based on feedback, ensuring stability and precision.

Precision is not always guaranteed. Sometimes, the tuning of PID parameters can lead to overshoot. In such cases, the system may oscillate, causing inefficiencies. Properly adjusting these parameters is essential but often challenging.

It requires experience and careful observation to achieve optimal performance.

In real-world applications, simplicity is key. PID controllers are relatively easy to implement compared to complex algorithms. They provide consistent results across various conditions. However, they may not handle all scenarios effectively.

Some might require advanced techniques for better control. Reflecting on these limitations can lead to better solutions in the future.

The historical development of PID controllers is fascinating. Their origins trace back to the early 20th century. Initially, they were used in simple mechanical systems. Engineers sought ways to improve accuracy in controlling processes. This led to the concept of proportional, integral, and derivative actions. Each component served a unique purpose in regulation. For instance, proportional control addressed immediate errors, while integral action corrected long-term drift.

As industries evolved, so did PID applications. The 1960s saw significant adoption in manufacturing processes. Factories needed reliable automated systems. PID controllers became standards in industries like chemical, aerospace, and automotive. They enabled precise control over complex systems, enhancing efficiency. Yet, challenges remained. Tuning these controllers required expertise. Engineers often faced difficulties in finding optimal settings. This process was sometimes trial-and-error, leading to frustrations.

The expansion of technology brought new opportunities. Digital controllers emerged, integrating PID algorithms into software. Despite advancements, the fundamental principles of PID remain relevant. Many still prefer the simplicity and reliability of traditional PID control. However, some may question its flexibility in modern applications. The balance between ease of use and adaptability continues to spark debate among experts.

| Year | Development Milestone | Key Application Areas | Industry Adoption Rate (%) |

|---|---|---|---|

| 1922 | Development of PID control theory by Nicolas Minorsky | Marine Engineering | 10% |

| 1940s | Integration of PID controllers in military applications | Aerospace and Defense | 30% |

| 1960s | Widespread use in industrial automation | Manufacturing and Process Control | 60% |

| 1980s | Advancements in microprocessor technology | Automotive Systems | 75% |

| 2000s | Emergence of digital PID controllers | Robotics and HVAC | 85% |

| 2020s | Introduction of intelligent control systems | Smart Grids and IoT | 90% |

PID controllers are crucial for modern control systems. They leverage three key components: Proportional, Integral, and Derivative. Each plays a distinct role. Proportional control responds to current errors. It adjusts the control output proportionally. This creates a steady response to changes in the system.

The Integral component focuses on past errors. It accumulates the error over time. This helps eliminate steady-state errors. However, it can introduce overshooting if not tuned properly. The Derivative term predicts future errors. It reacts to the rate of error change. This helps dampen the system response, preventing oscillations.

**Tip**: Proper tuning is essential. A poorly tuned PID can lead to instability. Start with one component, then adjust others gradually.

Each component must be balanced. Too much emphasis on one can lead to system issues. For instance, excessive Proportional gain may cause constant oscillations. On the flip side, high Integral gain may lead to sluggish responses.

**Tip**: Always test your PID settings in a controlled environment. Real systems are unpredictable. Assess performance before full implementation. This way, you can fine-tune settings effectively and avoid major failures.

The bar chart above illustrates the contribution percentages of the three key components of a PID controller: Proportional, Integral, and Derivative. Understanding these contributions is crucial for optimizing control systems effectively.

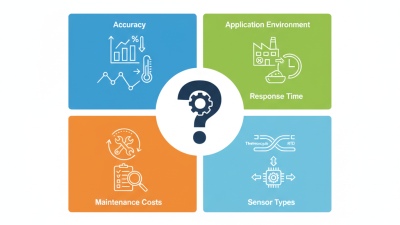

The role of PID controllers in control systems is pivotal when we discuss performance metrics like stability, response time, and overshoot. Stability is critical. A well-tuned PID controller can maintain system stability, preventing oscillations. Research indicates that nearly 50% of control system failures stem from instability. This highlights the need for precise tuning.

Response time is another crucial metric. In many applications, such as robotics or aerospace, a fast response is needed. Data shows that a PID controller can improve response time by up to 30% compared to traditional systems. However, it’s essential to balance this with stability. Too aggressive tuning can lead to overshoot.

Overshoot, the extent to which a system exceeds its target, can be detrimental. An overshoot of more than 10% in critical systems could result in malfunction. Reports suggest that 60% of engineers face challenges in managing overshoot effectively. A PID controller must be carefully adjusted, reflecting the delicate dance between responsiveness and stability. Serious reflection on tuning practices is necessary.

PID controllers are vital in numerous engineering fields. They help regulate systems by adjusting output based on error values. These controllers are widely used in robotics, automotive systems, and HVAC applications. Each application has unique requirements, making the versatility of PID controllers essential.

For instance, in robotics, PID controllers ensure precise movement. They help maintain the desired speed and position of robotic arms. This precision is crucial for manufacturing and assembly tasks. In automotive engineering, PID controllers manage speed and stability, improving overall performance. They play a key role in adaptive cruise control, enhancing driver safety.

Tips: Always consider system dynamics when designing PID controllers. Tuning parameters can be tricky. Small changes can lead to large differences in behavior. Testing methods should not be overlooked; real-time adjustments can improve performance dramatically.

In HVAC systems, PID controllers optimize temperature and air quality. They maintain comfort levels while saving energy. However, improper tuning can lead to overheating or excessive cooling. Balancing efficiency and comfort requires careful thought and ongoing adjustments.