Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

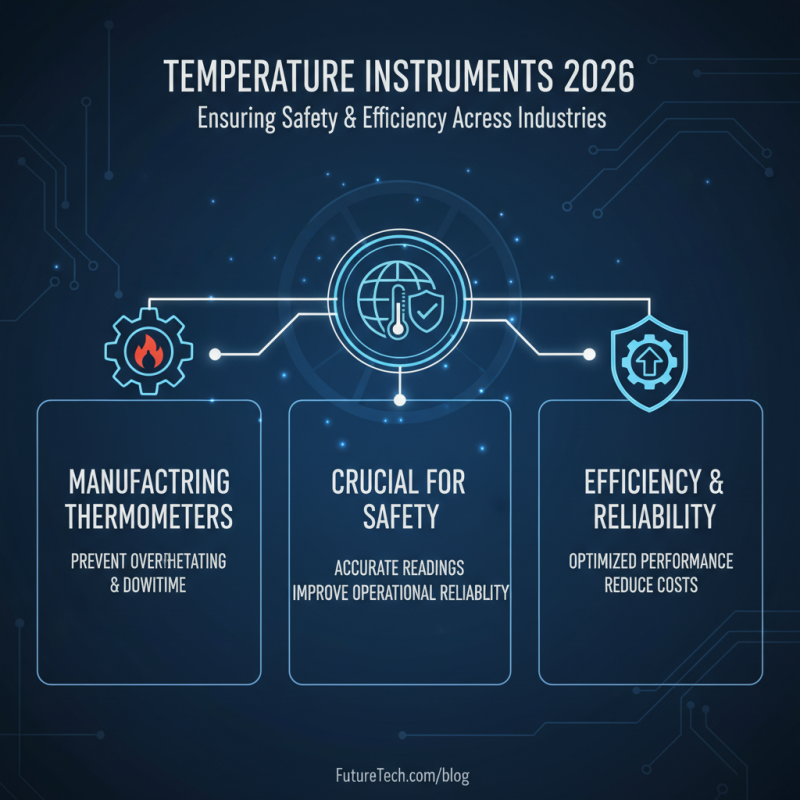

In the ever-evolving world of temperature measurement, having the right Temperature Instrument is crucial for various industries. According to a recent report by MarketsandMarkets, the temperature sensor market is projected to reach over $7 billion by 2026. This growth reflects the increasing reliance on precise temperature control in sectors like pharmaceuticals, food processing, and environmental monitoring.

Choosing the right Temperature Instrument can significantly impact your operations. In industries like healthcare, where compliance is essential, the accuracy of readings is non-negotiable. Poor choices can lead to costly errors, affecting product quality and safety. Moreover, outdated instruments may not provide the necessary data granularity needed for compliance and efficiency.

Yet, many businesses still overlook the importance of investing in advanced technology. Data from Frost & Sullivan indicates that over 30% of companies use outdated devices for temperature measurements. This could lead to inefficiency, jeopardizing product integrity and sustainability efforts. Select wisely—your choice matters.

When selecting temperature instruments for 2026, specific features are essential. Accuracy is a top priority. According to a report by the National Institute of Standards and Technology, precision can affect measurements by as much as 25% in certain environments. Look for instruments that maintain a margin of error within ±0.5°C.

Another critical feature is response time. In fast-paced industries, instruments with quick response rates save valuable time. Studies show that devices with response times under 1 second can improve efficiency by 30%. This speed is vital in settings like laboratories and food safety.

Tips: Always verify calibration standards when purchasing. Don’t overlook energy sources; battery life affects functionality. Consider ruggedness and IP rating for outdoor or industrial use.

Usability also matters. User-friendly interfaces lead to fewer errors. Reports suggest that intuitive designs cut training time by about 40%. Familiarize yourself with the options available, as not every instrument will meet your specific needs. Remember, the market is evolving rapidly; choose wisely.

In 2026, various industries will rely on advanced temperature instruments. These tools are crucial for ensuring safety and efficiency. In manufacturing, infrared thermometers will monitor equipment temperatures. They help prevent overheating, improving operational reliability. Accurate readings avoid costly downtimes.

In the food industry, thermocouples will be indispensable. They ensure that cooking temperatures are both safe and effective. Miscalculations in these settings can lead to food safety issues. Regular calibration of these devices is necessary and often overlooked.

Laboratories will benefit from digital temperature probes. These allow for precise readings in experiments. However, human error in handling them can lead to flawed data. Organizations need to train staff on the correct usage of these instruments. Proper training can enhance accuracy and reliability.

The landscape of temperature measurement technology is evolving rapidly. In 2026, devices will offer enhanced precision and user-friendly interfaces. New sensors will provide real-time data with greater accuracy. These innovations will cater to various industries, from healthcare to food safety. A compact, wireless thermometer might become essential for everyday use.

Tip: Always choose a device that fits your specific needs. Automated reminders can help monitor changes effectively. Don't overlook the importance of calibration, even with advanced models. Mistakes can happen, and recalibrating can prevent inaccuracies.

The integration of smart technology will redefine how we track temperature. Wearable sensors could provide crucial health insights. Yet, the reliability of these new devices raises questions. Can we trust the data they gather? Personal testing is key, as discrepancies may arise. Innovating can lead to improvements, but reflection on the technology's performance is vital.

Tip: Regularly review temperature data history. This practice can help identify patterns and potential issues. Engaging with your instrument's features fully enhances its utility. So, keep exploring ways to maximize your temperature measurement experience.

| Rank | Instrument Name | Type | Measurement Range | Accuracy | Features |

|---|---|---|---|---|---|

| 1 | Digital Thermocouple | Thermocouple | -200°C to 1200°C | ±0.5°C | Fast response time, multi-channel input |

| 2 | Infrared Thermometer | Non-contact | -50°C to 750°C | ±1.5°C | Laser targeting, adjustable emissivity |

| 3 | Thermal Imaging Camera | Imaging | -20°C to 500°C | ±2°C | Real-time thermal visualization, Wi-Fi connectivity |

| 4 | Smart Temperature Sensor | Wireless | -40°C to 125°C | ±0.3°C | IoT integration, mobile app monitoring |

| 5 | Bimetallic Temperature Gauge | Mechanical | 0°C to 300°C | ±2°C | Durable, can be used in harsh conditions |

| 6 | PT100 Temperature Sensor | Resistance | -200°C to 850°C | ±0.2°C | High accuracy, long-term stability |

| 7 | Thermistor | NTC/PTC | -50°C to 150°C | ±0.5°C | High sensitivity, compact size |

| 8 | Surface Temperature Probe | Contact | -100°C to 350°C | ±0.5°C | Flexible cable, quick response |

| 9 | Data Logger | Digital | -40°C to 125°C | ±0.5°C | Long-term monitoring, data storage |

| 10 | Wearable Temperature Monitor | Wearable | 30°C to 45°C | ±0.2°C | Continuous monitoring, alarm notifications |

As we approach 2026, the need for eco-friendly temperature instruments is becoming ever more critical. Traditional devices often contribute to environmental degradation. Reports indicate that electronic waste will increase by 21% globally by 2030 if current trends continue. This highlights the urgency for sustainable alternatives.

Innovative temperature instruments made from recyclable materials are on the rise. For example, biodegradable thermometers are being developed using natural substances. These choices reduce plastic waste significantly. A recent study revealed that sustainable instruments could cut carbon footprints by up to 30%. The shift toward eco-friendly design shows promise.

However, not all sustainable options are perfect. Some eco-friendly materials may not perform as well under extreme temperatures. This can lead to inaccuracies in critical environments. As we emphasize green choices, it’s crucial to balance performance and sustainability. The journey toward fully eco-friendly instrumentation requires careful consideration and ongoing innovation. The potential is there, yet challenges remain.

This bar chart illustrates the projected popularity of eco-friendly temperature instruments in 2026. The data showcases the top 10 instruments based on their sustainable features and user preferences.

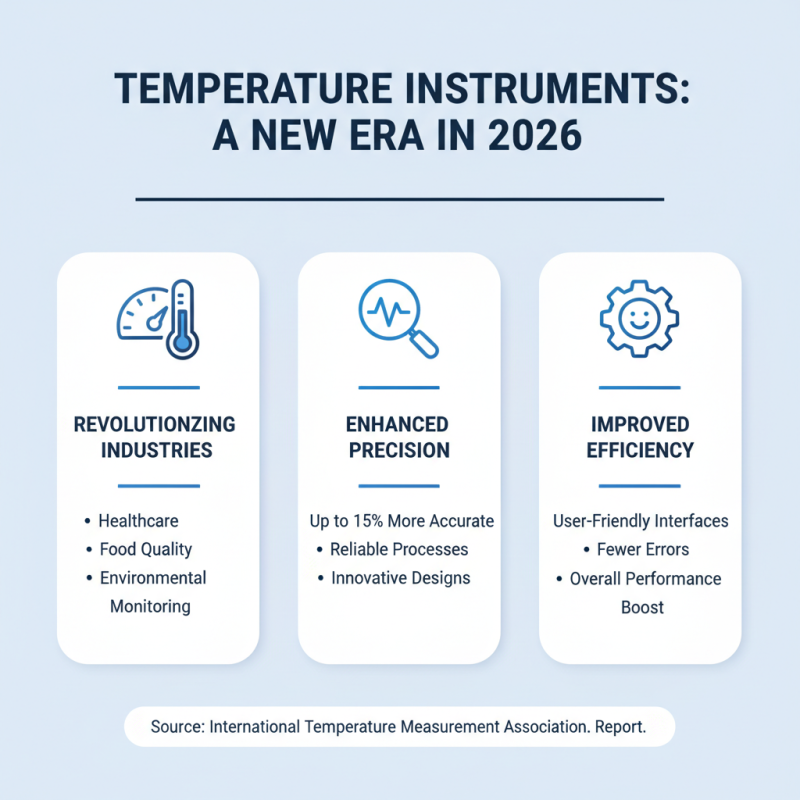

In 2026, user-friendly temperature instruments are set to revolutionize accuracy and efficiency in various industries. Recent studies indicate that innovative designs can improve measurement precision by up to 15%. These advancements can lead to more reliable processes in healthcare, food quality, and environmental monitoring. A report from the International Temperature Measurement Association highlights that simpler interfaces often lead to fewer user errors, enhancing overall performance.

The latest temperature sensors are compact yet powerful. Many models now feature digital displays that show readings in real time. Some devices even connect to smartphones via Bluetooth, allowing for remote monitoring. However, as great as this technology is, there are still improvements needed. Some users report confusion with calibration settings, which can lead to deviations in results. In practice, training staff to use new devices effectively can be time-consuming and sometimes inconsistent.

Temperature accuracy is critical. A study by the Heat Measurement Council reveals that 25% of temperature-related errors occur due to outdated calibration methods. With user-friendly interfaces, organizations can mitigate these risks. Yet, the reliance on technology may foster complacency. Users need to remain vigilant, regularly checking and recalibrating instruments. Balancing innovation with traditional methods is essential for optimal performance.